Future of water pipes

There is no uncertainty that new ideas in plumbing will develop. Huliot’s “Polypropylene pipe” pipes that can distinguish erosion and act like such train robots to play out a naturally fix from inside the funnel surface. Also, such “self-healing” pipes that can modify their size and divider thickness dependent on the funnel’s temperature, weight and speed to more readily suit changes in conduct use.

Need greater, more grounded channels toward the beginning of the day when everybody in a skyscraper high rise is showering and preparing for work, however littler, more slender funnels early afternoon when use is down? Simple. What about versatile, natural channels that can actually develop new branches to re-course around stops up? Is it sci-fi or would it be able to truly happen one day?

ClearBlack Features

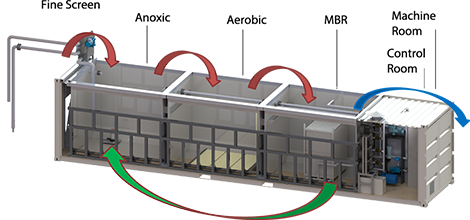

MBR- Membrane Bio-Reactor

ClearBlackTM is a modular wastewater treatment solution.

MBR- Membrane Bio-Reactor, combines biological and membrane technologies into one operating unit.

MBR processes can produce steady effluent of high quality to be discharged to coastal, surface or waterways or to be reclaimed for urban irrigation.

Smaller Footprint

ClearBlackTM MBR is significantly more compact than conventional treatment technologies. No need for large clarifiers or additional filters. A smaller tank, housing the membrane modules, replace the clarifier. In addition, the membrane allows higher sludge concentration in the bioreactor (MLSS). All this, together, with our smart engineering, makes ClearBlack™the most compact packaged treatment system in the market.

Excellent Effluent Quality

In the ClearBlackTM bioreactor, the biomass decomposes inorganic and organic pollutants while pathogens, viruses and macromolecules are completely retained in the system by the membrane. The membrane module serves as a complete barrier. Thus, high effluent quality is achieved with recycling and irrigations options. CLEARBLACK MBR produces treated effluent that complies and exceeds the highest local and international standards.

Lower Sludge Disposal Cost

In the ClearBlackTM system, the activated sludge formed in the bioreactor is at very high levels of MLSS. The excess sludge to be removed is more concentrated thus lowering the disposal cost.

NO Sand Filters, NO Activated Carbon

The membrane technology makes it unnecessary to use inefficient sand filters and activated carbon filters, which frequently tend to be clogged and require media replacement. In the ClearBlack™, solid removal is done by an integrated ultrafiltration (UF) membrane and includes automatic chemical and physical cleaning. This ensures higher reliability and lower operation.

Simple Operation

The ClearBlackTM is a simple and reliable system, tolerant to organic and hydraulic fluctuations producing steady high quality with minimal technician attendance. The process is automatic and remotely controlled.

Technology

ClearBlackTM System — conceptual process

No smells, no noise- The system can be integrated within crowded neighbourhoods, Industrial Parks, Campuses etc.

The system is working with high efficient aeration system controlled to work according to specific wastewater variations and site ambient conditions with low energy requirements

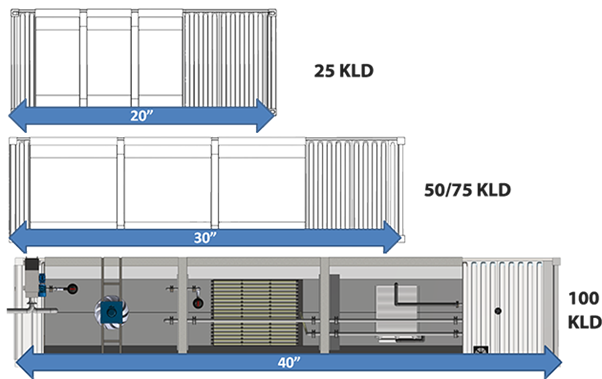

Modular and Flexible

The various ClearBlack™models can treat 25–100 m3/day of domestic effluents for reuse, per unit. Several units can be installed in parallel for higher capacity or future expansion.

The system can be installed underground or above ground, easily connected to the sewer system and to the treated water reservoir.

ClearBlackTM Benefits:

A compact system with an extra-small footprint

High effluent quality

Low operation cost per m³ of water

Low cost of maintenance

Totally autonomous

Total I.o.T. connectivity

Modular and flexible packaged units

No smells, no noise

Article Source: Medium.com

Comments

Post a Comment